- Get link

- X

- Other Apps

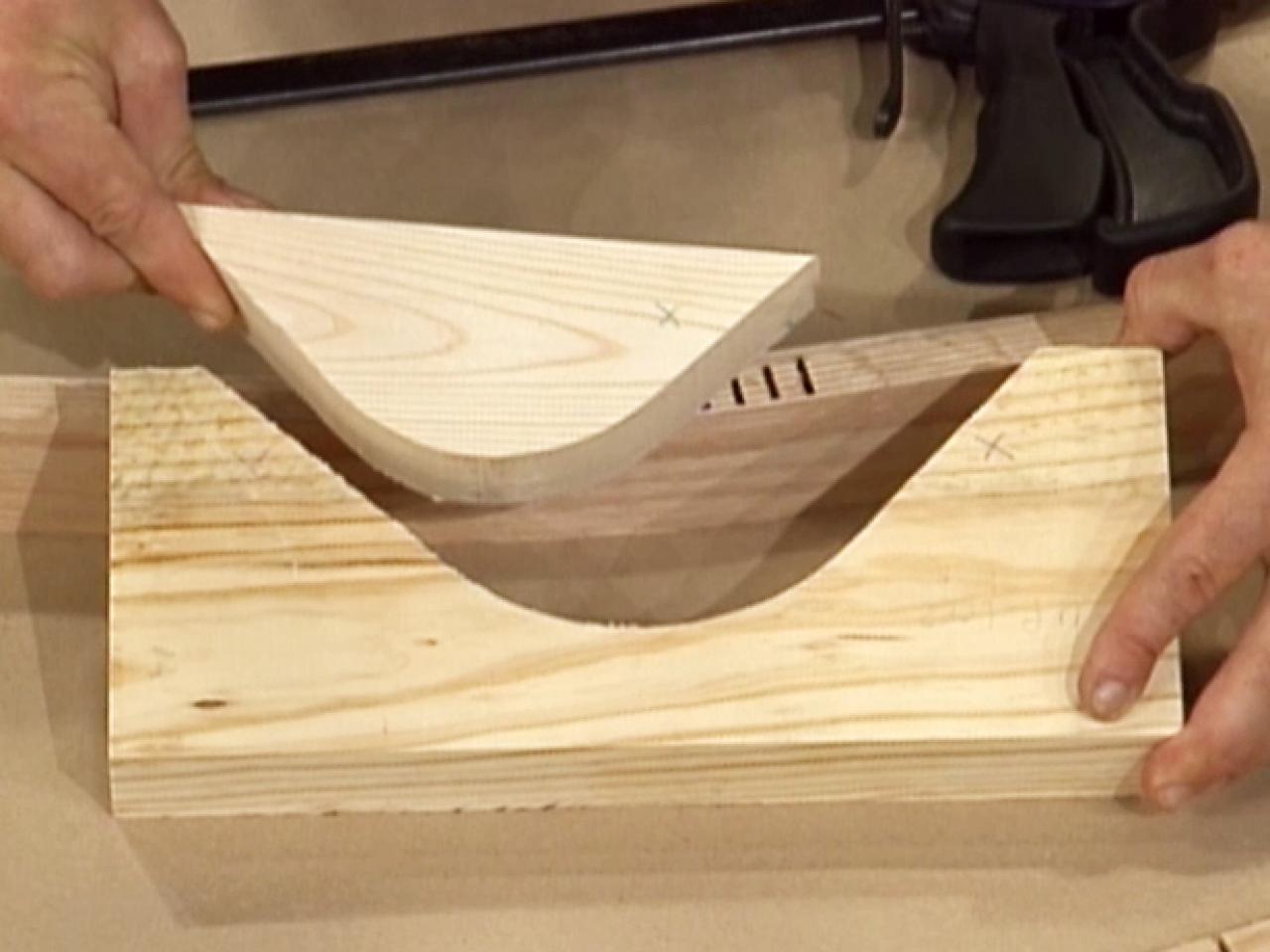

When it reaches 99. Cut out that piece and use it as the template for the other half.

This stuff tends to make a mess.

How to curve wood. Transfer the curve to the workpiece by cutting out the template and tracing along its edge. Curved wooden pieces could be made with a bandsaw expensive clamps and glues or heating the timber up to. Just be careful not the let the blade overheat and burn the wood.

Bent plastic wood makes a perfect curve. Allow the wood to sit overnight. Jig saw blades can bend with pressure thus causing your cut to be angled instead of square.

To avoid this dont try and force the blade through the cut. If you soak your boards use polyurethane glue to laminate them together. There are a number of ways to curve wood by hand.

A simple method for creating a curved railing using laminated strips. Jig saws use a motorized reciprocating blade to cut curves. After cutting and soaking the hardwood strips apply a coat of polyurethane glue to one side of each strip.

Polyurethane glue which needs moisture to work gives a long working time and fills gaps well. Bend wood to make furniture using a bent lamination technique that involves cutting wood into the desired shape ripping wood strips applying glue with a ro. Be sure to wear gloves.

Position the cutout piece from the U-shaped jig on top of the cutout side of the work piece. For symmetrical shapes with multiple curves draw exactly half of the shape on plywood hardboard or paper. Please let us know your experience re.

No steam is requiredThe Excel file containing the equation for the curvature is found. Remember that you already own an array of templates for simple shapes. A structure called a steambox is usually built to immerse the wood in an environment with high temperature steam and humidity.

Use a wood blade with a narrow profile that will allow for sharper curves. The trick is to keep the blade speed up but advance the tool slowly to prevent the jarring bouncing effect so familiar with these beastly tools. They are great for quickly cutting curves into wood along a drawn line.

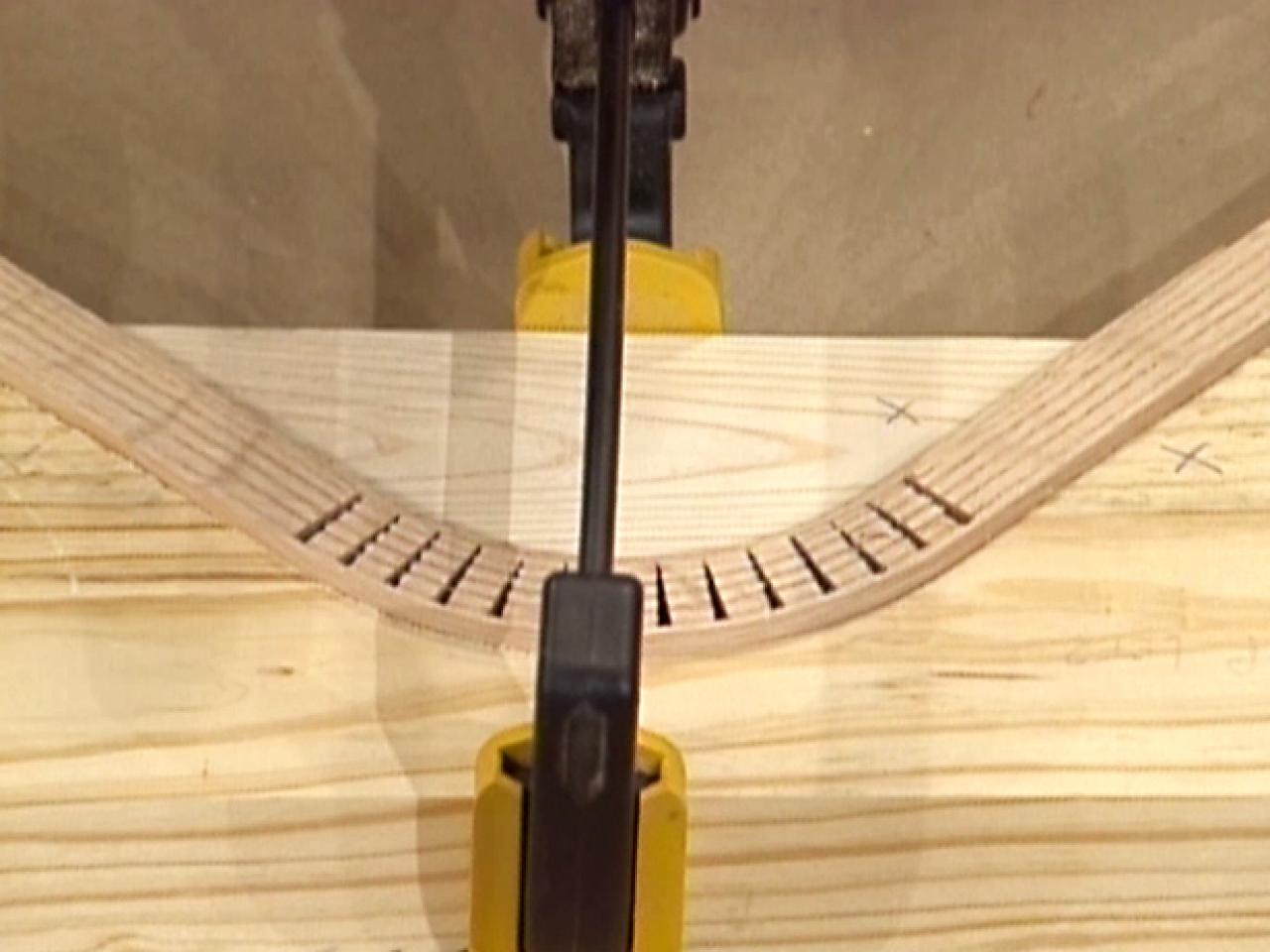

Often you can simply eyeball the best curve for the job by bending a piece of wood and using it as a template. Adjust the position of the blocks to change the curve. Geometrically more closer and thinner kerf cuts should give a smoother curve -- Less and wider cuts may give a curve with segments having sharper bends at the kerf cut.

Clamp all three pieces together so the work piece bends inside U-shape curve Image 2. Optimal actual curves using different wood min thickness kerf thickness etc. Clamp blocks to a 22 and spring-fit a length of 12 plastic wood between them.

Place the U-shaped jig underneath the work piece Image 1.

Learning How To Bend Wood Using A Steam Cleaner Woodworking Youtube

Learning How To Bend Wood Using A Steam Cleaner Woodworking Youtube

Making Curved Wood Panels For Furniture Bending Wood Tips And Techniques Woodarchivist Com How To Bend Wood Curved Wood Diy Woodworking

Making Curved Wood Panels For Furniture Bending Wood Tips And Techniques Woodarchivist Com How To Bend Wood Curved Wood Diy Woodworking

Woodworking Technology Curved Wood How To Make Logs Curved Wood Finishing Kitchen Cabinets Youtube

Woodworking Technology Curved Wood How To Make Logs Curved Wood Finishing Kitchen Cabinets Youtube

How To Curve Or Bend Wood Ukod Blog

How To Curve Or Bend Wood Ukod Blog

How To Curve Wood Cut The Wood

How To Curve Wood Cut The Wood

Five Fun Ways To Curve Wood Australian Wood Review

Five Fun Ways To Curve Wood Australian Wood Review

Curve Bending Before Fabricate Into Truss How To Bend Wood Wood Beams Wood Truss

Curve Bending Before Fabricate Into Truss How To Bend Wood Wood Beams Wood Truss

How To Bend Wood Best Methods Start Woodworking Now

How To Bend Wood Best Methods Start Woodworking Now

How To Bend Wood How To Bend Wood Diy Woodworking Woodworking

How To Bend Wood How To Bend Wood Diy Woodworking Woodworking

Comments

Post a Comment