- Get link

- X

- Other Apps

400 The form is made from simple materials. The one-piece construction of the Century step requires no assembling no form-work no labor for installation.

Forming A Set Of Cement Steps Part Two Youtube

Forming A Set Of Cement Steps Part Two Youtube

Once the Century concrete step is installed maintenance is nonexistent for decades.

Concrete step forming. Forming and pouring concrete steps Sawcut your form lumber and finish corners. Ad Search What Is Concrete Cutting. Get Results from 6 Engines at Once.

Sawcut all but the bottom step forms at a 45-degree angle. Get Results from 6 Engines at Once. This allows for finishing right up to the corner of the step.

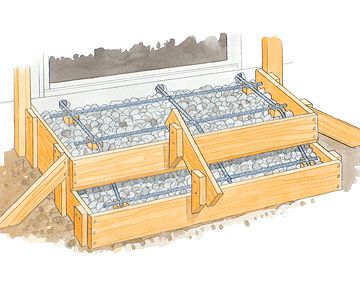

The Concrete Step Wizard is a step forming system designed to reduce labor and material costs while improving productivity when forming stairs. The thickness of the slab will determine the spacing of the stakes as well as the nominal dimension of the forming lumber. When installing concrete steps you have to make sure that you build the right number of steps for the height of the entrance.

Odell doesnt bevel the bottom of the 2x8 because the knife edge is easily buried in concrete. There are no stairs too wide or too numerous for the Concrete Step Wizard. Before building the steps you have to make a wood form or frame into which to pour the concrete.

Give the faces and edges of concrete steps a wide array of textures patterns and profiles. Add a 24 sometimes called a strongback to the front of each steps form boards. 2x8 ripped to the height of the riser plywood nailers plywood gussets Tapcon screws and a 2x4 brace.

The part of the step under the riser form is trowelled smooth after the form is removed. This will keep the pressure of the concrete from bowing out the boards. Heres how to build a form for two concrete steps.

Reinforce the step form board. Concrete step forms and liners are used for achieving decorative patterns on step faces. Place the form board starting at one corner alongside the string line staking it down about 18 inch 03 cm from the line with sharpened wood stakes.

This form will be a hollow model of your steps. The Century step is portable manufactured of high strength lightweight steel reinforced concrete for durability and convenient installation. This versatile system makes stair forms easy to assemble makes lumber stringers and risers reusable and can be used to form any stair in the building code.

Ad Search What Is Concrete Cutting.

How To Build Concrete Steps Custom Concrete

How To Build Concrete Steps Custom Concrete

Concrete Step Form Liners Pouring Concrete Steps Concrete Steps Cement Steps Concrete Stairs

Concrete Step Form Liners Pouring Concrete Steps Concrete Steps Cement Steps Concrete Stairs

How To Build Concrete Steps Custom Concrete

How To Build Concrete Steps Custom Concrete

How To Make Floating Concrete Steps Mid Century Modern Interior Designer Portfolio

How To Make Floating Concrete Steps Mid Century Modern Interior Designer Portfolio

How To Pour Concrete Steps Better Homes Gardens

How To Pour Concrete Steps Better Homes Gardens

How To Construct Concrete Stairs

How To Construct Concrete Stairs

Forming Concrete Steps Concrete Construction Magazine

Forming Concrete Steps Concrete Construction Magazine

Concrete Step Form Liners Pouring Concrete Steps Youtube

Concrete Step Form Liners Pouring Concrete Steps Youtube

How To Pour Concrete Steps Better Homes Gardens

How To Pour Concrete Steps Better Homes Gardens

The Art Of Concrete Stairs Concrete Stairs Concrete Staircase Concrete

The Art Of Concrete Stairs Concrete Stairs Concrete Staircase Concrete

Building Concrete Steps How To Build Concrete Steps And Stairs Video

Building Concrete Steps How To Build Concrete Steps And Stairs Video

Concrete Porch Steps Concrete Floor Stain Concrete Flooring

Concrete Porch Steps Concrete Floor Stain Concrete Flooring

A Beginner S Guide To Pouring Concrete Steps

A Beginner S Guide To Pouring Concrete Steps

Cantilevered Stair Tread Details Keith Messick Architecture

Cantilevered Stair Tread Details Keith Messick Architecture

Comments

Post a Comment